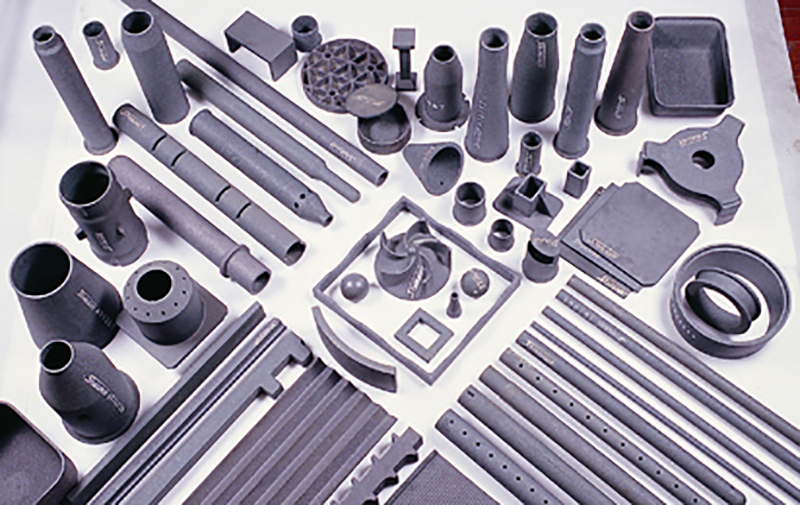

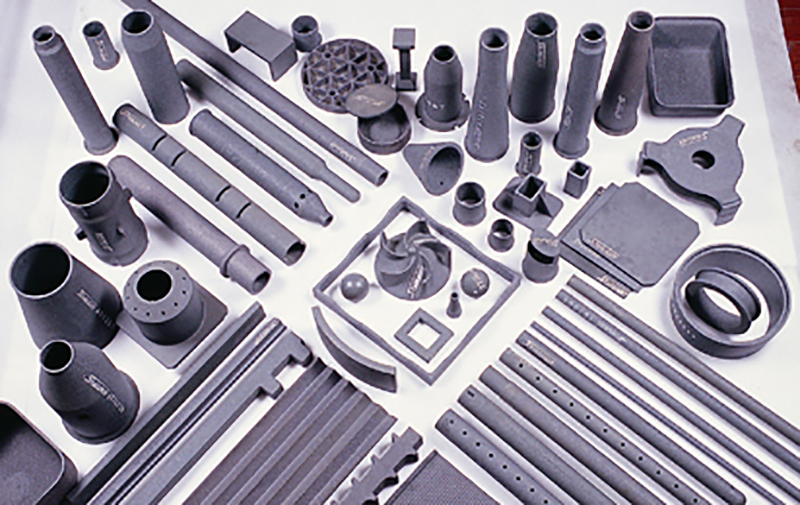

Yeniden Kristalleştirilmiş Silisyum Karbür Yapısal Parçalar

1. Yeniden kristalleştirilmiş silisyum karbür yapısal parçalarımız son derece yüksek sıcaklık dayanımına sahiptir.

2. Rsic yapısal parçalarımız yüksek saflığa ve iyi korozyon direncine sahiptir.

3. RSIC Yapısal Parçalarımız mükemmel aşınma direncine sahiptir.

- STARLIGHT

- Şenyang, Çin

- Sipariş edilen ürün miktarına göre

- 500t/yıl

ayrıntılar

Introduction to Recrystallized silicon carbide structural parts:

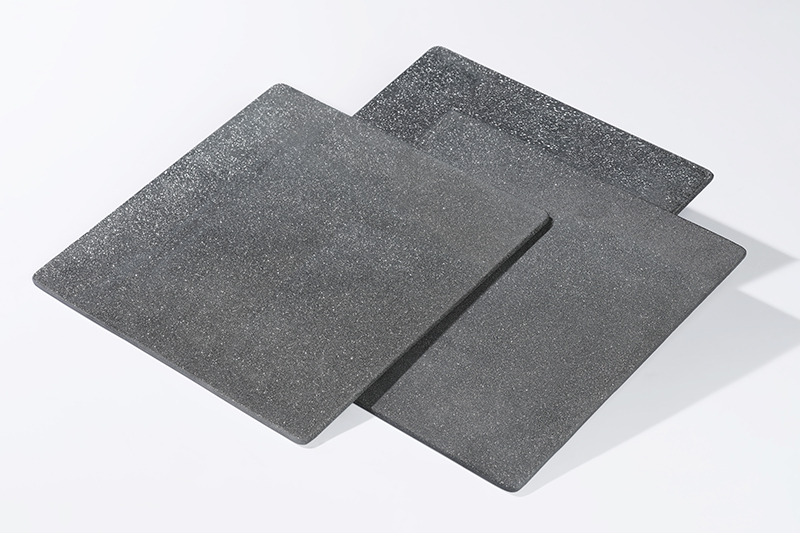

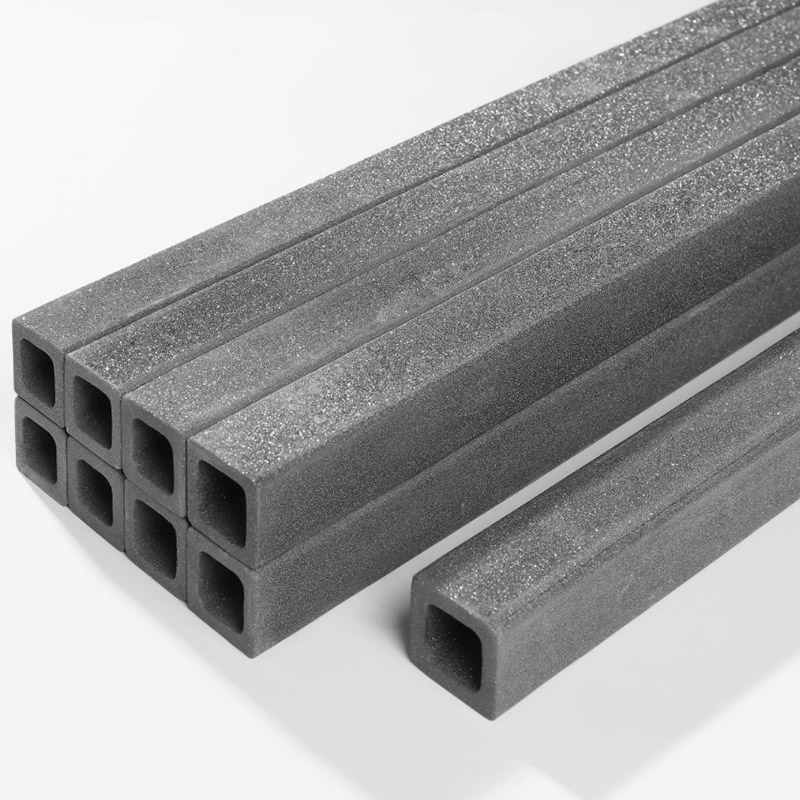

Recrystallized silicon carbide ceramic products are components made from ceramic materials obtained through high-temperature treatment. It uses silicon carbide particles as raw materials, and through high-temperature heat treatment, the particles are recrystallized to form a dense, polycrystalline ceramic material. Recrystallized silicon carbide ceramic products are widely used in high-temperature industrial furnaces, thermal equipment, chemical equipment, and other fields.

Advantages of Recrystallized silicon carbide ceramic products:

Recrystallized silicon carbide ceramic products are widely recognized for their exceptional performance in extreme environments. Recrystallized silicon carbide ceramic products' primary advantages stem from the unique properties of silicon carbide combined with optimized recrystallization processes.

1.Recrystallized silicon carbide ceramic product exhibits outstanding high-temperature stability, maintaining mechanical strength and dimensional integrity at temperatures exceeding 1,650°C. This surpasses the limits of most metals and oxide ceramics, making it ideal for furnace fixtures, kiln furniture, and aerospace applications.

2.Recrystallized silicon carbide ceramic products' superior thermal conductivity (≈120 W/m·K) and low thermal expansion coefficient ensure rapid heat dissipation and resistance to thermal shock, critical for semiconductor processing equipment and radiant burners.

3.RSIC Structural Part demonstrates excellent corrosion resistance to acids, alkalis, and molten metals, outperforming traditional refractories in harsh chemical environments.

4.RSIC Structural Part' high hardness (Mohs 9.5) and wear resistance significantly extend service life in abrasive applications like grinding systems or shot blast nozzles. Additionally, R-SiC components are lightweight compared to metallic alternatives, reducing energy consumption in high-speed operations.

Environmentally, RSiC's durability minimizes material waste and maintenance downtime. With customizable porosity and near-net-shape manufacturing capabilities, it offers cost-efficiency for complex geometries. These attributes position RSiC as a premium material for industries demanding reliability under thermal, mechanical, and chemical stress.

Application of Recrystallized silicon carbide structural parts:

1. Recrystallized silicon carbide structural parts are widely used in various industrial furnaces, such as ceramic furnaces and steel furnaces.

2. RSIC Structural Part is used to manufacture key components such as high-temperature valves, seals, and heat exchangers.

3. RSIC Structural Part is also suitable for manufacturing chemical equipment such as reactors, pipelines, and fillers, and has excellent corrosion and high temperature resistance performance.

4. RSIC Structural Part is also applied in the manufacturing of high-temperature components in fields such as aerospace, automotive, and electronics.

Regarding us:

The company has advanced production and research and development equipment, mainly producing recrystallized silicon carbide, silicon nitride bonded silicon carbide, and reaction sintered silicon carbide products, providing high-quality energy-saving kiln furniture, high-temperature kiln accessories, and other structural components for the ceramic and related industries.

Ürün Etiketi

Son fiyat olsun? En kısa sürede cevap vereceğiz (12 saat içinde)